- HOME

- Products

- Automotive and Industrial Machinery

- Engine parts

Engine parts

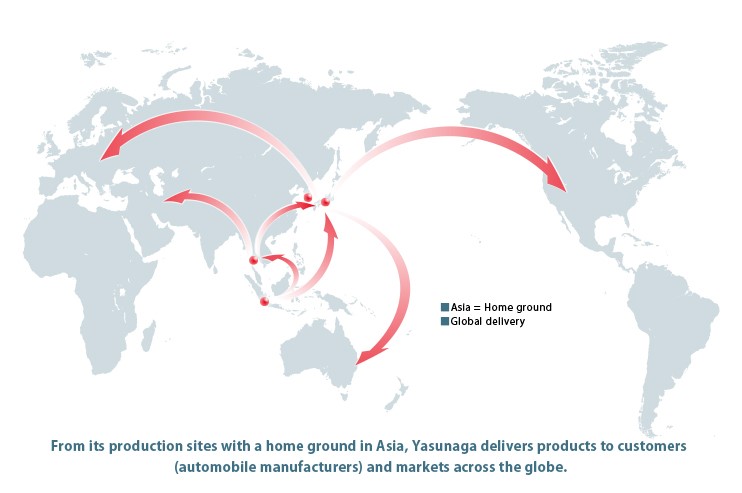

Global Expansion through Production Sites with a Home Ground in Asia

■5C parts

Precision processing of engine parts for automotive and industrial machinery is our group's primary business. We offer products meeting customer needs on the basis of production results and engine-related expertise earned through a wide range of undertakings.

We produce the key "5C" parts of engines, including connecting rod and cylinder head in our flexible production lines to supply them worldwide.

Connecting rod

Connecting rod

| Features | Connecting rods, placed between piston and crankshaft converts the linear reciprocating motion of piston to a rotary motion for engine power transmission. They are subject to extremely high mechanical impacts, rotational moments and high temperatures. |

|---|---|

| Use in automotive, industrial and farming machinery engines. Yasunaga manufacture connecting rods for engines from 2 cylinders to 8 cylinders. | |

| Now that connecting rods are most essential automotive engine parts, most of them are manufactured by automobile manufacturers in their own in-house plants. We are capable to manufacture such production lines in our machine tools division and to set them up through inter-divisional technology collaborations. |

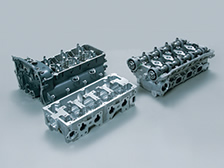

Cylinder head

Cylinder head

| Features | Cylinder head located on a cylinder block is a device having functions to absorb combustible gases, ignite and drive out exhaust air. Most of engines comprising the device is computerized with electronic control. |

|---|---|

| Use of aluminum became more prevalent. Cylinder head itself is so sophisticated as to require quite an advanced processing technology. Our high-level technological capability is now satisfying customers' requirements. |

Cylinder block

Cylinder block

| Features | The core parts in internal combustion engines where energy from ignition and combustion is transmitted to pistons and crankshafts for a revolution power. |

|---|---|

| For gasoline and diesel engines for automotive, farming and industrial machines, ranging from 1 up to 6 cylinders. | |

| From materials to finished products high precision processed products can be produced with our advanced technology. |

Camshaft

Camshaft

| Features | Key components of engine valve systems, camshafts drive the rocker arms and tappets that open and close valves. The number used varies with the form of the engine. |

|---|---|

| Yasunaga has established a continuous production system, based on advanced manufacturing technology, that spans materials to machining to logistics, using methods such as induction quenching that assures surface hardness in cast iron camshafts. | |

| To reduce weight, we carry out mass production and delivery of hollow camshafts. |

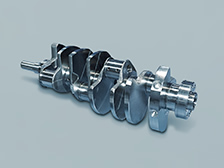

Crankshaft

Crankshaft

| Features | Crankshafts play the role of converting into rotational motion the linear reciprocating motion of pistons and connecting rods generated by combustion and expansion processes in engine pistons. They are important key components that are subject to high-speed rotation and a high-impact environment. |

|---|