- HOME

- Product information

- Engine Parts business

We contribute to the creation of a sustainable mobility society through our manufacturing technology.

This division is engaged in precise machining of engine parts for vehicles and industrial machinery, one of our main businesses. Connecting rods are our main products, for which we hold the world's largest share in the niche market.

We are taking on the challenge of new fields for electrification vehicles with the extensive machining experience and knowhow throughout our long-term business activities.

Automotive/industrial engine parts

Automotive/industrial engine parts Parts other than engine parts

Parts other than engine parts Introduction of casting technologies

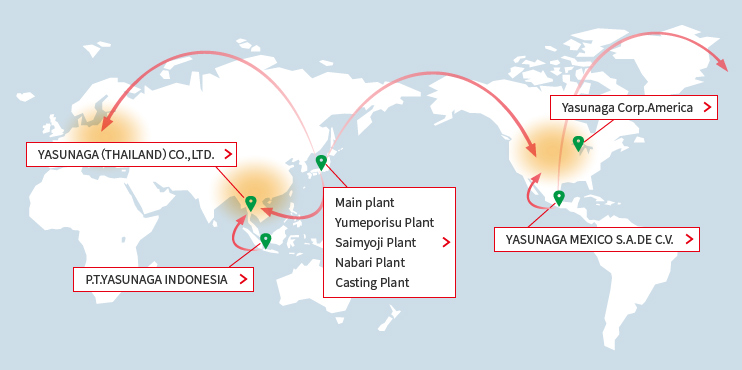

Introduction of casting technologies Global network

Global network

History of Our Engine Parts Business

-

1960s - Transferred engine parts processing facility from a Car OEM to our main plant and initiated our own machining of cylinder blocks and cylinder heads.

- Established Nabari Plant.

- Dedicated our business to engine part processing.

Transferred machining line to the main plant

Transferred machining line to the main plant Established Nabari Plant

Established Nabari Plant Cylinder head

Cylinder head Cylinder block

Cylinder block1970s - Implemented our own process designed line for machining cylinder blocks and cylinder heads.

- Initiated machining of connecting rods as a new 5C engine part.

Our own process-designed machining line

Our own process-designed machining line The first product machined through our own process-designed line

The first product machined through our own process-designed line Started machining connecting rods

Started machining connecting rods1980s - Established Saimyoji Plant.

- Assigned Saimyoji Plant as our dedicated plant for connecting rods.

- Established a joint venture in North America to expand our business.

Established Saimyoji Plant

Established Saimyoji Plant Opened sales office in North America

Opened sales office in North America1990s - Implemented our own designed concept of connecting rod machining lines to increase flexibility for high-mix low-volume requirement.

- Established P.T.Y.Indonesia to meet demand for connecting rod machining localization in Indonesia.

Established flexible lines for connecting rods

Established flexible lines for connecting rods Designed/implemented high-mix low-volume machining line for connecting rods

Designed/implemented high-mix low-volume machining line for connecting rods Established a manufacturing plant in Indonesia Machining connecting rods on flexible lines

Established a manufacturing plant in Indonesia Machining connecting rods on flexible lines2000s - Established Yumeporisu Plant.

- Expanded case/block related machining capacity (cylinder block/cylinder head) to handle aluminum die-casted/cast iron materials.

Established Yumeporisu Plant

Established Yumeporisu Plant Manufacturing on flexible lines

Manufacturing on flexible lines2010s - Established machining plants in South Korea, Thailand, and Mexico.

- Fulfill local procurement requirements around the world.

- With the acceleration of power-train electrification, enhanced efforts toward machining technologies for next generation vehicles.

Established a machining plant in South Korea

Established a machining plant in South Korea Established a machining plant in Thailand

Established a machining plant in Thailand Established a machining plant in Mexico

Established a machining plant in Mexico Electric hydraulic brake components

Electric hydraulic brake components

Main customers

Aisin Takaoka Co., Ltd.,

Kubota Corporation, JATCO Ltd.,

Suzuki Motor Corporation,

Daihatsu Motor Co., Ltd.,

Toyota Motor Corporation,

Toyota Industries Corporation,

Nissan Motor Corporation,

Mitsubishi Motors Corporation,

Mitsubishi Heavy Industries Engine & Turbocharger, Ltd.,

UD Trucks Corporation

General Motors Company,

Fiat Chrysler Automobile,

Hyundai Motor Company,

Stellantis N.V.

- * (Japanese) alphabetical order