Machining equipment

-

FC4ST

Compact machining center for heavy duty cuttings

Single-spindle horizontal machining center mainly for mass-produced parts such as shaft type workpieces.

With Z-axis column traverse and a highly-rigid roller LM guide for each axis, this machining center is capable of heavy duty cutting of iron workpieces. In spite of its high rigidity, it retains a small footprint.- Target workpieces: Crankshaft, Camshaft

FC4ST-W

Machining center for long and shaft type workpieces

Single-spindle horizontal machining center for mass-produced parts such as shaft type workpieces.

With Z-axis column traverse and a highly-rigid roller LM guide for each axis, this machining center is capable of heavy duty cutting of iron workpieces.

Compared to FC4ST, this machine has a longer X-axis stroke, making it capable of machining long workpieces and box-type workpieces.- Target workpieces: Crankshaft, Camshaft, Cylinder block, Cylinder head

F24ST

Higher productivity achieved with double spindles

Double-spindle horizontal machining center for mass-produced parts such as connecting rods and small workpieces.

By implementing more jigs and machining simultaneously with two spindles, it is capable of higher productivity.

This allows the machine to contribute to higher productivity in a smaller footprint.- Target workpieces: Connecting rod, Small parts

Finish boring machine

Stable high quality boring

This dedicated machine tool is designed for finishing processes that require high quality, such as large and small end holes for connecting rods.

We can propose optimal clamping force, orders, and other related items based on our experience.- Target workpieces: Connecting rod, rocker arm, etc.

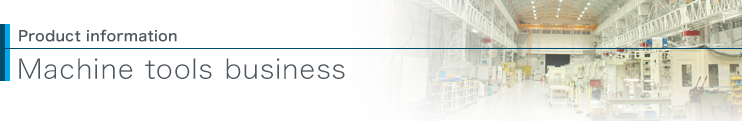

Micro finisher

Highly versatile micro finisher for various needs

This machine is capable of finishing surface roughness with high accuracy requirements.

It can be customized for various purposes, such as multi-types and shift types.

We can propose flexible micro finishers for high-mix low-volume production.- Target workpieces: Crankshaft, Camshaft, other shaft type workpieces

Process-specialized equipment

-

Finish boring machine

Stable high quality boring

This dedicated machine tool is designed for finishing processes that require high quality, such as large and small end holes for connecting rods.

We can propose optimal clamping force, orders, and other related items based on our experience.- Target workpieces: Connecting rod, rocker arm, etc.

Fracture splitting machine

Domestic top share—From fracture splitting to assembly of connecting rods.

This machine can fracture connecting rods with an impacting structure and assemble caps and rods against the joint face.

By integrating multiple processes, it helps reduce the required floorspace when compared to conventional methods.- Target workpieces: Connecting rod

Fracture joint face inspection

Non-contact, high-speed, highly-accurate fracture joint face quantitative management

This machine inspects the joint face surfaces of fractured connecting rods using our original 3D inspection technologies. It acquires accurate fracture surface profiles, allowing evaluation of the surface area and overlay position.

- Target workpieces: Connecting rod

Micro finisher

Highly versatile micro finisher for various needs

This machine is capable of finishing surface roughness with high accuracy requirements.

It can be customized for various purposes, such as multi-types and shift types.

We can propose flexible micro finishers for high-mix low-volume production.- Target workpieces: Crankshaft, Camshaft, other shaft type workpieces

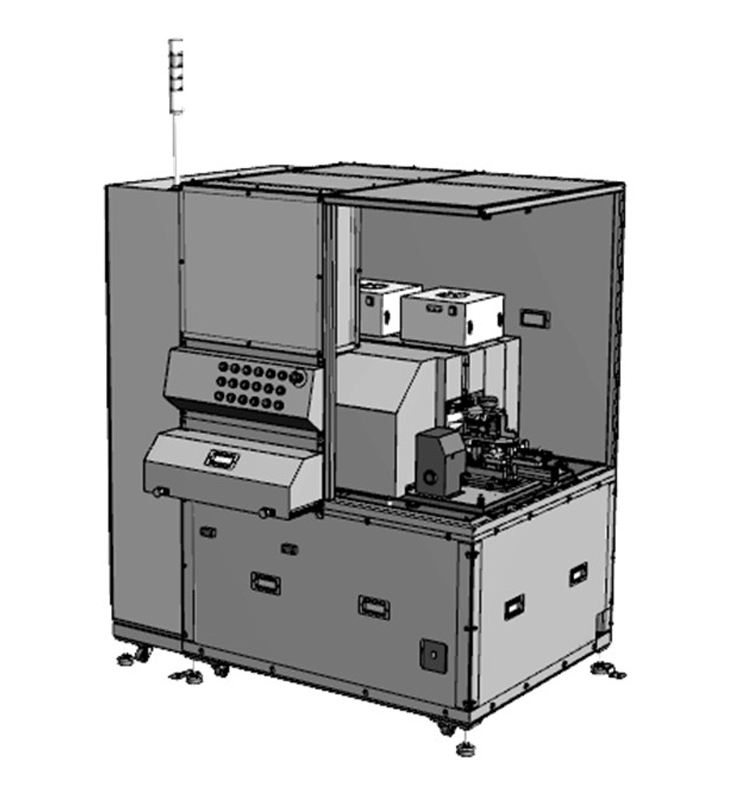

Leak tester

Highly productive leak tester

This is a differential pressure leak tester that automatically detects leaks from box-type workpieces such as cylinder blocks and cylinder heads.

We can help solve your problems by proposing masking solutions and flexibility for different types based on our experience.- Target workpieces: Cylinder block, Cylinder head, Other box-type workpieces

Dr. Leak

Flexible injection leak tester just like a doctor’s stethoscope

A tester for sealant application, injection, and leaks. This tester is mounted on a single-spindle machining center.

Compared with dedicated leak testers and robot leak testers, this machine offers easier shaft alignment and programable adjustments like machining centers.

Additionally, this machine is versatile due to numerically controlled axis adjustment.- Target workpieces: Cylinder block, Cylinder head

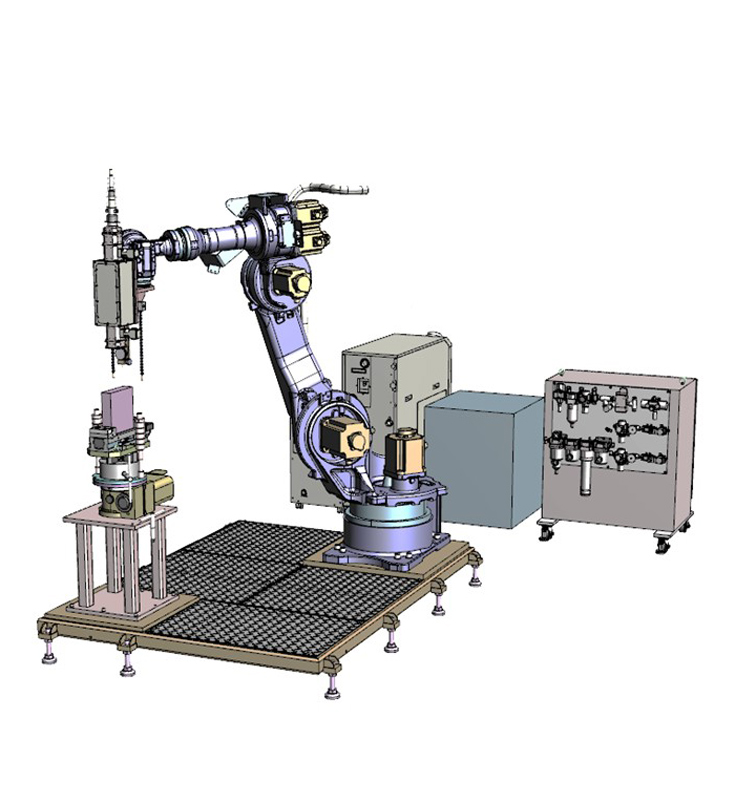

Laser type quenching machine

Yasunaga's laser technologies meet various needs

We have developed this quenching technique for internal process equipment production. Applying this technique to multi-joint robots and index tables allows it to quench components in any shape. This does not require dedicated coils used for high-frequency quenching, and it is possible to program single items through simple teaching.

We can also help solve your problems using our expertise in special machine production and laser engineering.- Target workpieces: Various workpieces

Customized machine tools

Utilizing our experiences in specialized machine tool production, we are capable of proposing machines that fit your requirements.

We can help customers solve many problems, such as space and cycle time, that arise when replacing aging equipment.